The Sisom Bucket

Hot Products

The HCN’ skid steer pick-up sweeper is a practical attachment for sweeping, collecting, and dumping dirt and other job site debris. Equipped with 26’’ diameter poly/steel wire mix bristles and kept with sufficient room for the bristles to collect dirt and debris toward the attached bucket, this sweeper is designed to work efficiently and is long-lasting. Other features include the bolt-on replaceable cut edge, protective rubber skirting, durable hydraulic motor, height-adjustable metal shroud, and more!

A case drain line, the 3/8’’ hydraulic hose, is added to adapt for the newer version of skid steers to release the hydraulic pressure built up in the motor, which will alternatively extend the life span of the motor. If your skid steer is older or does not have a port for the third hose, it is safe to use this sweeper but keep the case drain line plugged. This sweeper cannot work with high-flow skid steer loader

The sweeper’s hydraulic motor spins durable bristles mounted to its rotating drum. Powerful flicking action sends dirt and debris flying into the attachment’s collection bucket. Bristles spin in either direction.

When moving the loader in reverse, you can scrape mud and caked-on debris with the bucket wear-edge as you sweep the material into the bucket – similar to sweeping with a hand broom and dustpan. When traveling forward, the bristles send material flying forward against a rubber flap. From there, materials travel over the top of the bristles and into the bucket. When forward sweeping, keep the wear edge above the surface for optimum performance and wear edge life.

Ideal for all sweeping conditions, these tough, poly bristles provide excellent flicking action for effective debris removal. The heavy-duty bristles have 15% more poly than standard bristles for superior sweeping and long life. Our new sweepers feature larger diameter sweeper wafers compared to our previous models, which increase bristle life with better cleaning ability to pick up more debris.

Product Details

How to work

During operation, tough, poly bristles flick debris into the sweeper collection bucket – and when it’s full, you can lift, dump and dispose. It does the work of multiple clean-up attachments with optimal bristle-to-surface contact and highly productive efficiency. It’s ideal for site cleanup, daily dust abatement, road construction, airport maintenance and more.

Features:

· Durable direct-drive hydraulic motor

· Bi-directional collection broom sweeps in forward and reverse

· Poly/steel wire mix bristles

· Rubber skirting to contain debris

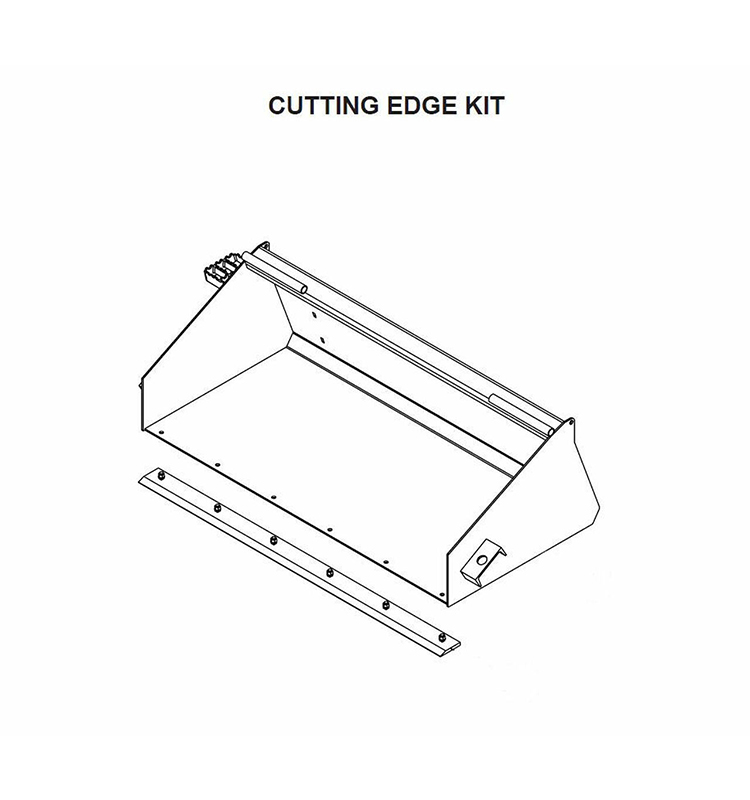

· Replaceable bolt-on cutting edge

· Motor and shaft guards

· Height adjustment screw with six positions

· Heavy-duty dump stops

· Grease fittings on all pivot points and bearings

· Shroud protects objects flying debris

· Universal skid steer quick attach

· Case drain line (3/8’’ hydraulic hoe) added to release the motor pressure

Specifications:

· Working width:60" 72",84"

· Number of wafer: 41

· Wafer diameter: 26"

· Core diameter: 8”

· Bucket capacity: 0.6 cubic yards

· Hydraulic flow: 10-25 GPM

· Skid steer loader power recommended: 45-75 HP

Packaging:

· Packed in a metal shipping crate

· Shipping dimension: 88” x 54” x 32”

· Shipping weight: 1150 lb

0202 Heavy Duty Bucket Sweeper

Model | Mini020245 | 020260Ⅰ | 020272Ⅰ | 020284Ⅰ |

Over length (mm) | 1220 | 1450 | 1450 | 1450 |

Over width (mm) | 865 | 1817 | 2117 | 2466 |

Over height (mm) | 405 | 926 | 926 | 926 |

Height product (without support spring) (mm) | 405 | 680 | 680 | 680 |

Over weight(kg) | 180 | 456 | 480 | 540 |

Bucket capacity (m3) | 0.1 | 0.39 | 0.46 | 0.56 |

Working width (mm) | 990 | 1530 | 1830 | 2130 |

Brush Dia. (mm) | φ400 | φ660 | φ660 | φ660 |

Allow maximum pressure (Mpa) | 20 | 21 | 21 | 21 |

Flow(L/min) | 30-40 | 60-80 | 60-80 | 80-90 |

OPTIONAL | Atomizing dust removal system | |||

Side brush cleaning system | ||||

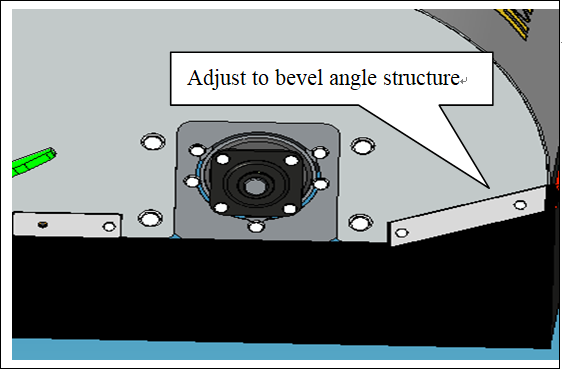

| The front end of the upper cover is changed to a sloping angle structure, in order to improve the utilization rate of the brushes and ensure that the front end of the upper cover is not worn. |

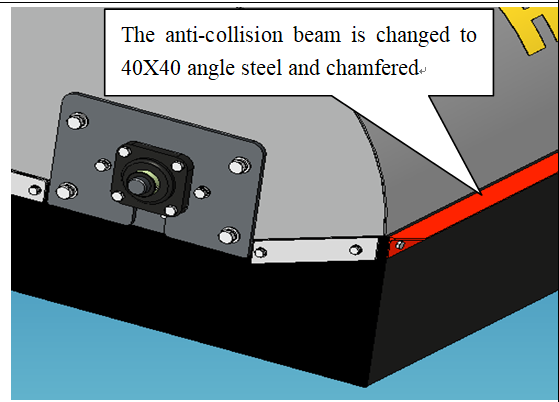

| The anti-collision beam is adjusted to 40X40 angle steel, and there are chamfers on both sides to prevent accidental scratches. |

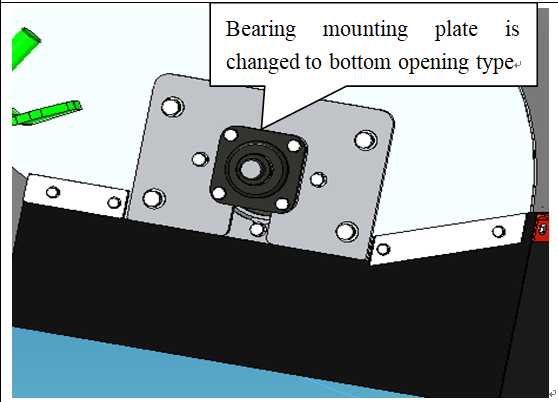

| The bearing mounting plate is changed to the lower open type, which is convenient for the disassembly and assembly of the brush without disassembling the bearing. |

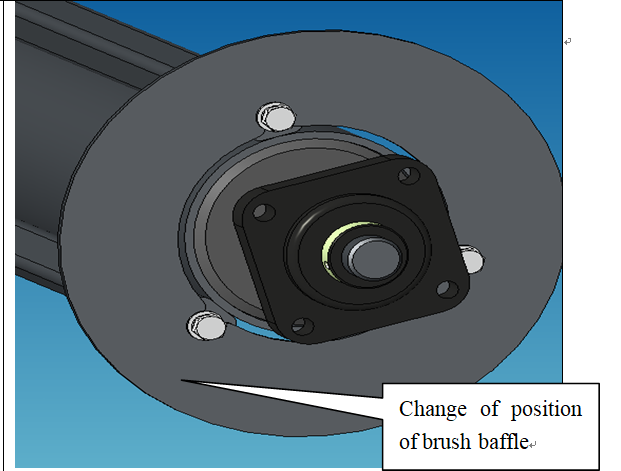

| The bearing mounting plate is changed to the lower opening type brush baffle. The position of the baffle is changed from the original inner mounting plate of the mandrel to the position of the mandrel square tube. The purpose is to facilitate the disassembly and assembly of the brush without disassembling the bearing. |

Previous Page

Next Page

XUZHOU HCN ATTACHMENTS MANUFACTURE CO.,LTD

Power by: cnwangju.com Sitemap