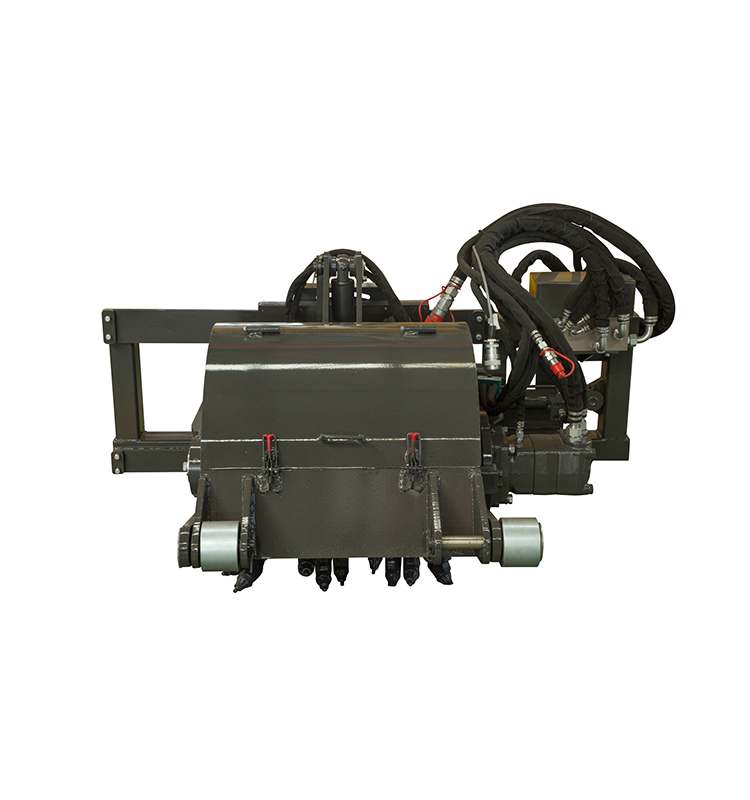

0206 Skid Steer Cold Planer

Hot Products

HCN’ Cold Planers are designed for small paving jobs in residential and commercial applications, and are primarily used to economically restore asphalt and concrete surfaces.

They are ideal for milling imperfections prior to resurfacing, removing deteriorated pavement, removing traffic lane stripes, scarify rough the road and jobs where the use of dedicated planers is limited.

Product Details

Features:

Direct drive system

Direct drive system on the 020618I high flow, features a hydraulic radial piston motor to ensure maximum

cutting rate and drum torque for optimal production performance and efficiency.

Two Direct-Drive Motors for 020640

With a direct-drive motor on each side of the drum, you get increased torque force which also increases productivity and the life of the planer.

Self-leveling design

Self-leveling design automatically levels cold planer when placed on the ground for consistent depth control without operator adjustments and excellent spoil retention.

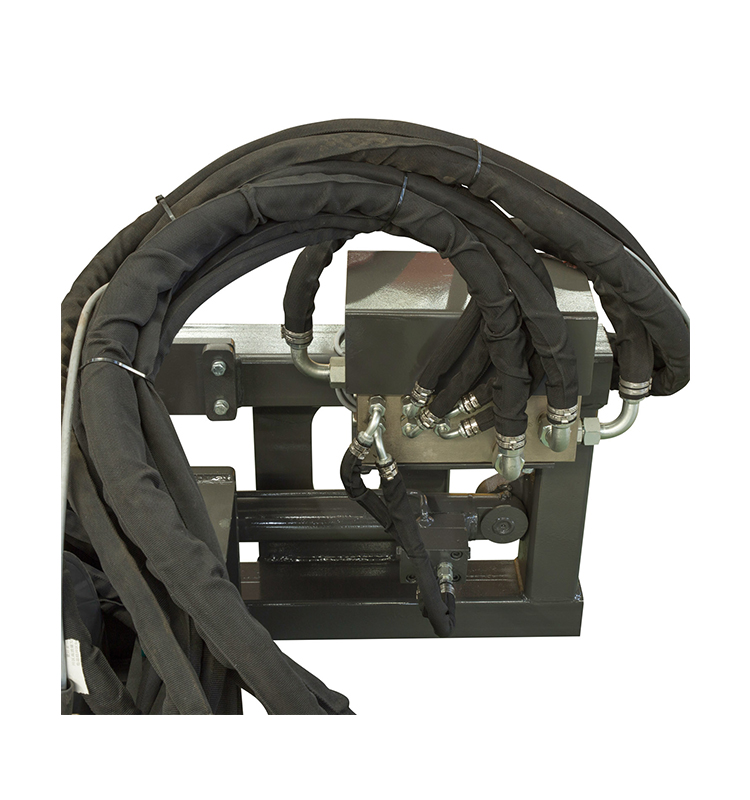

Float, spring tilt and hydraulic tilt

Float enables planers to follow the contour of the surface. It is activated by turning a handle and is only available high flow, high flow planers. Spring tilt and hydraulic tilt enable planers to oscillate for angled cuts. Tilt is hydraulically controlled on high flow models and spring controlled on standard flow planers.

Max Pro Pressure Gauge

Max Pro Pressure Gauge provides operator feedback to adjust ground speed for maximum productivity in changing material loads. Gauge displays planer performance in real-time conditions and is visible from the cab. Standard on all models.

Hydraulic side-shift

Hydraulic side-shift permits close planing to curbs, walls and other obstructions.

Independent left/right depth control

Independent left/right depth control allows maximum drum depths to be adjusted independently on each skid. Gauges are easily viewable from the cab. Independent depth control is mechanical on the 020618I models; hydraulic independent depth control is standard on the 020618I models.

Cut Mark

Indicates contact point of drum with surface based on depth of cut, so an assistant can communicate with the

operator when to start and stop the cut.

Drum Center Indicator

Indicates center of the drum on the side of the planer.

Bit Options

All purpose conical bits are standard. Optional concrete bits, heavy duty concrete bits, and heavy duty asphalt

bits are also available. Tools to change out the bits are included.

Optional Integrated Water Tank and spray system

Model | 020618I | 020640 |

Overall Length (mm) | 1215 | 1100 |

Overall Width (mm) | 1760 | 1660 |

Overall Height (mm) | 970 | 880 |

Working Width (mm) | 450 | 1000 |

Working Depth(mm) | 170 | 130 |

Side moving distance(mm) | 600 | 600 |

Work Flow(l/min) | 120-140 | 120-200 |

Pressure (MPa) | 21 | 21 |

Operating voltage (V) (optional) | DC12/24 | DC12/24 |

Weight(Kg) | 950 | 1150 |

Optional | Teeth for asphalt or Cement and spray system

| |

0206 series Cold Planer

The value and popularity of HCN’ skid steer cold planer attachments are becoming increasingly more evident because of the variety of jobs they can assist with. In addition to small milling jobs in which large milling machines can't efficiently be used, cold planers are an effective tool for asphalt and concrete pothole and frost heave repair, curb cutting, pavement texturing for improved skid resistance, and the removal of traffic lane stripes and roadway around manholes. This product is also available CE ceritified.

Planetary drive delivers high torque

High rear spoil clearance to prevent recirculation of material

Protective shields for hydraulic and electrical components

Efficient piston drive motor

Optional water tank available with adjustable mounting brackets to fit most skid steer loaders

Model | 020612 | 020618 | 020620 |

Overall Length (mm) | 1376 | 1376 | 1376 |

Overall Width (mm) | 1727 | 1727 | 1727 |

Overall Height (mm) | 935 | 935 | 935 |

Working Width (mm) | 300 | 450 | 500 |

Working Depth(mm) | 150 | 150 | 150 |

Turning distance(mm) | 600 | 600 | 600 |

Flow(l/min) | 120-130 | 130-140 | 130-140 |

Pressure (MPa) | 21 | 21 | 21 |

Operating voltage (V) (optional) | DC12/24 | DC12/24 | DC12/24 |

Weight(Kg) | 580 | 887 | 980 |

Description

Highly versatile Cold Planers are adaptable to a wide variety of job environments including road repair, bridge deck repair, landscaping, municipal, shopping center and utility work. The Cold Planer is easy to maneuver around manhole and storm drains; excellent for bridge decks where heavier, dedicated planers are not allowed. Hydraulic side-shift and depth control allows skid steer operators to shift it up to 24” for maneuvering close to buildings and other obstacles from the comfort of your seat.

Features

Adjustable to a wide variety of job environments including road construction, landscaping, bridge deck repair, municipal, shopping center, and utility work

Easy to maneuver around manholes and storm drains; excellent for bridge decks where heavier dedicated planers are not allowed

Two tools in one; cut asphalt and concrete with the same machine

Side-shift feature moves planer from left to right for maximum maneuverability

· The High Flow Cold Planer from HCN Attachment has been designed for industrial-grade concrete milling and resurfacing. To ensure reliable and durable performance, HCN Attachment has sourced some of the most trusted components in the industry. The high drum weight of this unit, combined with the construction and design of the tooth patten, greatly reduces vibration, leading to more efficient operation across the board. High-end components include: Danfoss piston motor, high quality planetary hub, Double hung drum with large bearing on non-motor side. Tooth design features: Rocket Fin teeth and V-Tooth pattern setup.

· When you're on the job, putting your equipment to the test, you need attachments that are reliable and you can trust. Fine adjustment and grade control is made possible thanks to adjustable side runners, while HCN Attachment large access over makes for easier (and safer) tooth replacement.

More than 20 years of deep cultivation in the machinery industry, more than 20 designer and engineers, and 200 staffs.28000 square meters modern standard workshop, More than 400 kinds high quality attachments with 1000 models, Choice of quality, HCN Attachments

HCN Machinery is a wholly-owned subsidiary of Sino Equipment Research Institute, a national high-tech enterprise. In the year of 1991, introduced GEHL skid steer loader and attachments production technology, established specialized company in 2008. With more than 20 years of ingenuity in construction industry, it has become a professional construction machine and attachments manufacturer which integrating R & D, production and design. There are more than 400 types products with more than 1000 specifications, mainly including Skid Steer Loader and Attachment, Wheel Loaders and Attachments, Mini Skid Steer Loaders and Attachments , Compact Loader and Attachments which are widely used in construction and municipal project, road construction, agriculture and forestry, landscape, environmental sanitation, snow and ice removal, and so on various fields .

HCN Machinery, from the product design,we are searching for top quality raw materials, such as STRENX ,HARDOX steel section bar and plates,BOSCH REXROTH ,SAUER-DANFOSS, EATON hydraulic components .so our high quality and high reliability products, has won the favor of customers and become a well-known brand in the world. 90% of our products are exported to the United States, Canada, Russia, Australia etc, a lots of countries. With sincere service and excellent quality, it has been expanding a big market in the world.

Always persist in the independent R & D strategy, relying on the strong technical strength of Sino Equipment Research Institute, the only enterprise which manufacture attachments has obtained the approval vendor certification of bobcat, JCB, Caterpillar, XCMG, Liugong, Lingong and Zoomlion, and has become their qualified supplier, continuously improves the production technology and quality, and is committed to building products with core competitiveness.

1.Q:Are you a factory or trading company?

A: We are a factory.

2.Q:Where is your factory located?

A: Our factory is in XUZHOU City, JIANGSU Province, China.It's near Qingdao & Shanghai port.It's about three hour from Shanghai by high speed train.

3.Q:How about quality control in your factory?

A:"Quality is first, Customers are friends".We are top Skid steer loader and attachments manufacturer in China, we are certified with CE GHOST

4.Q:How about guarantee?

A: It's within twelve months after goods is discharged in the destination. During that period,if some breakdown easily spare parts need to change, my factory offers free.

5. Q:What certificate you have?

A: We have the certificate of CE GHOS etc

6. Q: Overseas service available?

A: yes, we have global service network

Previous Page

Next Page

XUZHOU HCN ATTACHMENTS MANUFACTURE CO.,LTD

Power by: cnwangju.com Sitemap